The RCHPB frame is built using only high quality mild steel, the welded construction provides the structural stability to ensure consistent performance with minimal deflection.

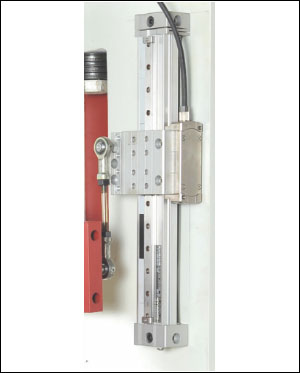

High Resolution Linear Scale

Provide Precision ram position feedback

CNC Controller Cybtouch � 8P

7” Touchscreen Controller ( X & Y Axis )

Easy Operating

User Friendly

Easy Communication

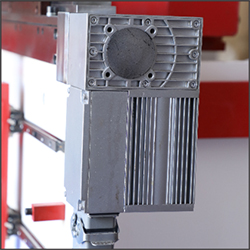

Reliable Hydraulic System

International reputation hydraulics components

Specially designed manifolds gives smoth noiseless & jerkless function

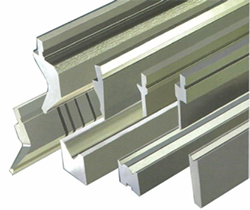

Quality toolings & Accessories ( Optional )

Purvaj offer complete line of high accuracy certified

premium toolings, European style precision ground toolings

and new standard precision tooling harden and grounded tooling for long life & high accuracy.

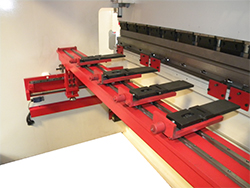

Quick Release Clamp ( Optional )

A cost effective efficient solution for quick tool changes.

Standard Backgauge

CNC servo position control on X axis and Z1 / Z2 are move on LM guide

Servo CNC back gauge with Precision ball screw and linear guide way ensures maximum rigidity for high productivity speed and high accuracy.

Auto Crowning System ( Optional )

Auto Crowning system for precise degree

Auto Lubrication System

Auto Lubrication System

Centralized Lubrication system with auto control

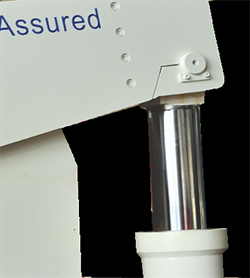

Rear Cylinder Design

Rear Cylinder Design

Rear cylinder design using mechanical advantages through lever, reduces the cylinder size which enable to use medium pressure hydraulic component and also improves stoke accuracy

341, GIDC Por, Ramangamdi, Por,

Vadodara, Gujarat - 391243, India.

+ 91 98257 68697

0265 - 2988697